Advancing Thermal Insulation And Flow Assurance Solutions For Subsea Infrastucture

Necessity Drives Innovation

For decades, the subsea answer to inherent problems in existing insulation technology has been to make compromises, spend money to engineer around the challenges, or simply pray that pre-qualification testing goes well. ODYSEA felt that there was a better way, A Simpler Way, than continuing to increase complexity or bear additional risk. We have made a commitment to leverage a new material technology platform to solve our customers’ problems with complexity. That means continuous investment in innovative material and process development to produce more efficient and reliable thermal insulation and flow assurance solutions. Successfully executing Shell’s Appomattox project utilizing these methods, we become convinced that it was worth the time and resource commitment to apply our learnings and deliver a truly innovative approach to the biggest problems in this segment of subsea infrastructure. ODYSEA combines cutting-edge materials science, streamlined process engineering and a focus on operational efficiency to provide robust solutions so project teams globally can rest easier.

INNOVATION IS IN OUR DNA

The ODYSEA team is able to develop agile, flexible solutions to serve our customers and offer options that do not exist today including unmatched levels of speed and mobility to drive customer wins. We like to collaborate, understand the big picture and push your thinking by asking first principle questions so we can harness the power of our innovations to provide better, safer and less risky answers that deliver for clients.

INNOVATIVE MATERIAL PLATFORM

ODYSEA has exclusively partnered with ExxonMobil to utilize Proxxima™ resins as single-layer insulation materials in our GDLXTM solution. Proxxima is a family of norbornene thermoset resins that utilize the Nobel prize-winning Grubbs Catalyst technology. These materials were destined for subsea service with benefits including inherently low k-values making them great insulators with no depth limitation. By nature of their molecular structure, they also have no chemical susceptibility to seawater and are extremely hydrophobic, resisting water uptake that can damage insulation properties.

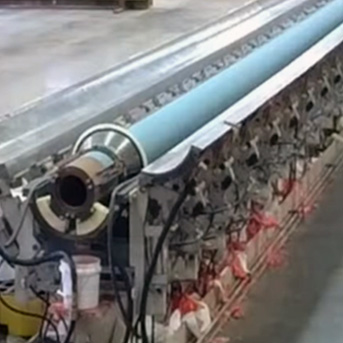

INNOVATIVE MOBILE-FIRST PROCESSING PLATFORM

ODYSEA’S vision has always been to build an innovative company addressing key subsea infrastructure challenges around the world. To meet that vision, the hardware to support the process has always been designed with a “mobile-first” philosophy – skid-mounted pieces that can be easily assembled or disassembled and transported in standard, high-cube containers. Further, since GDLXTM only requires one thermal coating material that can be low-pressure molded onsite, clients have greater flexibility in scheduling. Fewer types of material and easily transportable equipment also open up new possibilities to serve remote locations in a safer, easier and more efficient manner.

Innovative Application

“The ODYSEA process is as simple as 1, 2, 3.”

FBE Pipe in Mold

Molding Process Underway

GDLX Pipe Complete

CONTACT US TODAY

Ready to learn more about how ODYSEA found a simpler way to address subsea thermal insulation’s challenges? Contact us today.